The Coca-Cola Production Journey

Discover how one of the world’s most beloved beverages transforms from simple ingredients into the iconic drink enjoyed across the globe.

This presentation explores the fascinating manufacturing process behind Coca-Cola, from initial ingredient preparation to worldwide distribution.

The Secret Formula

Guarded Recipe

The original formula remains one of the world’s best-kept trade secrets.

Flavor Base

The secret “7X flavor” contains a proprietary blend of natural ingredients.

Limited Access

Only a select few employees know the complete formula.

Historic Origins

The formula dates back to 1886, created by pharmacist John S. Pemberton.

Ingredient Preparation

Water Purification

Water undergoes extensive filtration and treatment. Advanced systems remove impurities and standardize mineral content.

Sweetener Mixing

High-fructose corn syrup or sugar is precisely measured. The sweetener solution is prepared according to strict specifications.

Concentrate Addition

The secret concentrate is carefully added. This flavor base gives Coca-Cola its distinctive taste.

The Mixing Process

Base Preparation

Treated water forms the foundation of every batch.

Sweetener Integration

Sweetener solution is blended with precise timing.

Concentrate Addition

The secret flavor concentrate gives Coca-Cola its signature taste.

Carbonation

Carbon dioxide is infused under pressure for those signature bubbles.

Quality Control Checkpoints

Ingredient Testing

Each raw material undergoes laboratory analysis.

- Purity verification

- Contaminant screening

Syrup Analysis

The mixed syrup is sampled hourly.

- Sugar concentration

- Acidity levels

Taste Testing

Trained tasters evaluate each batch.

- Flavor profile

- Consistency check

Final Inspection

Finished product undergoes final verification.

- Carbonation level

- Fill volume

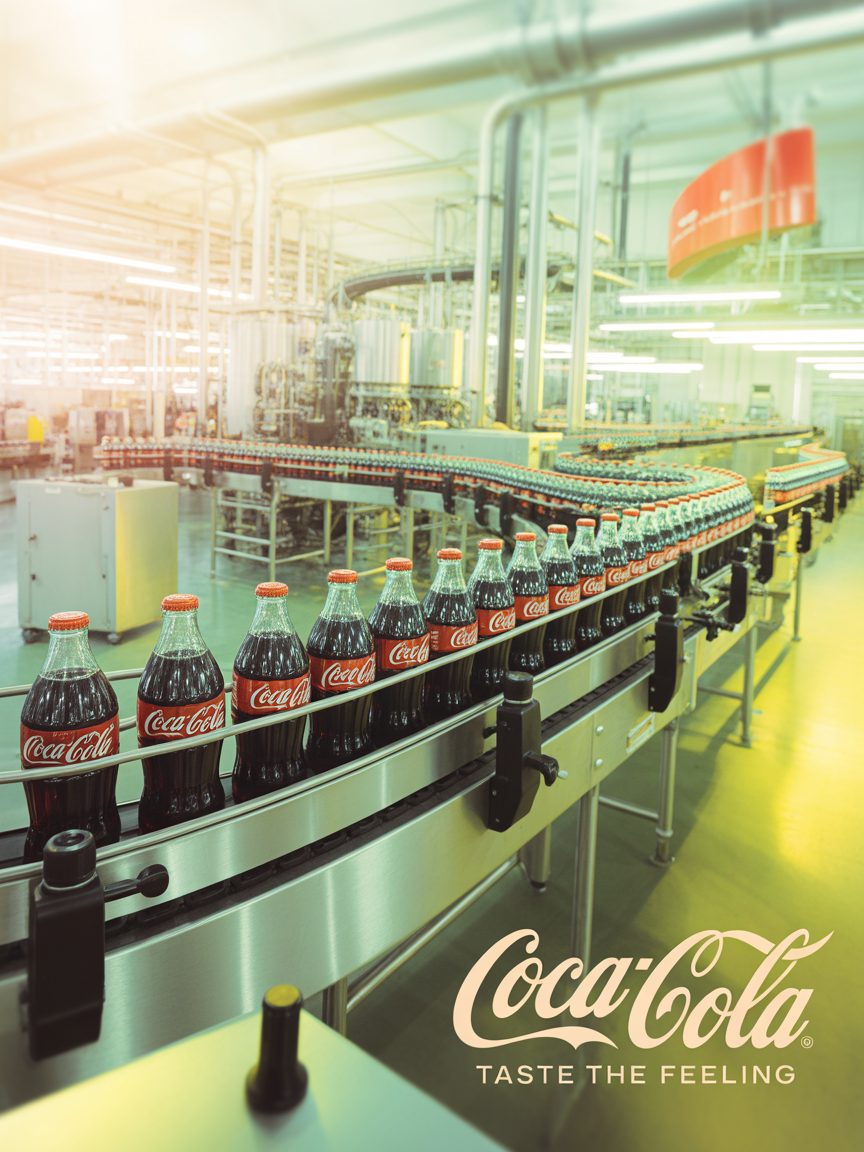

Bottling and Packaging

Container Preparation

Bottles or cans are sterilized with high-pressure water jets. Each container is inspected for defects.

High-Speed Filling

Modern machines fill up to 2,000 containers per minute. Precision equipment ensures exact fill volumes.

Sealing

Bottles receive caps while cans get lids. Vacuum seals ensure freshness and prevent leakage.

Packaging

Containers are grouped into packs. Robots stack and wrap finished products onto pallets.

Global Distribution Network

Production Facilities

Over 900 bottling plants worldwide

Distribution Centers

Regional hubs optimize delivery routes

Transport Fleet

Custom trucks deliver to local retailers

Retail Partners

Available in over 200 countries

Coca-Cola’s complex logistics network ensures fresh product reaches consumers worldwide. The company utilizes advanced tracking systems to monitor inventory and delivery status in real-time.

Sustainability Initiatives

Water Stewardship

Coca-Cola aims to return 100% of water used in production to nature and communities. Advanced treatment plants clean wastewater before release.

Packaging Innovation

The company is developing plant-based bottles. Their “World Without Waste” initiative aims to collect and recycle every bottle sold by 2030.

Carbon Reduction

Manufacturing facilities are implementing renewable energy solutions. Improved refrigeration systems reduce greenhouse gas emissions.